No reason I can scientifically justify that, I just thought it might best to keep their centers of gravity close to one and other in the same plane. I thought it would be best to hang the wayrod and VTF weight(s) at the same height as the cartridge (slightly below the level of the tonearm). It sounds like the wayrod is too far out on your setup. If you don't have a tracking force gauge, then follow the above advice on setting tracking force. Then I use the main counterweight to fine tune the tracking force when using the gauge. I set the wayrod weight to the correct tracking force on the wayrod first. I use a Shure SFG-2 tracking force gauge to set the tracking force. Make sure you have the stylus guard down when doing this!! When the wayrod lateral setting is correct, I then put the main counterweight back on. Once you have the correct wayrod lateral weight setting, the arm will have no left or right pull to it when lifting the arm up and down. If the arm pulls towards the left, increase the wayrod lateral weight setting. If the arm pulls to the right while our lifting it up and down, back off on the wayrod lateral weight setting.

Then I lift the tonearm by grabbing it at the straight part of the arm, moving the arm up and down. Set the wayrod weight to the combined weight of the cartridge and mounting hardware. Move the wayrod lateral weight as far back on the wayrod as it will go.

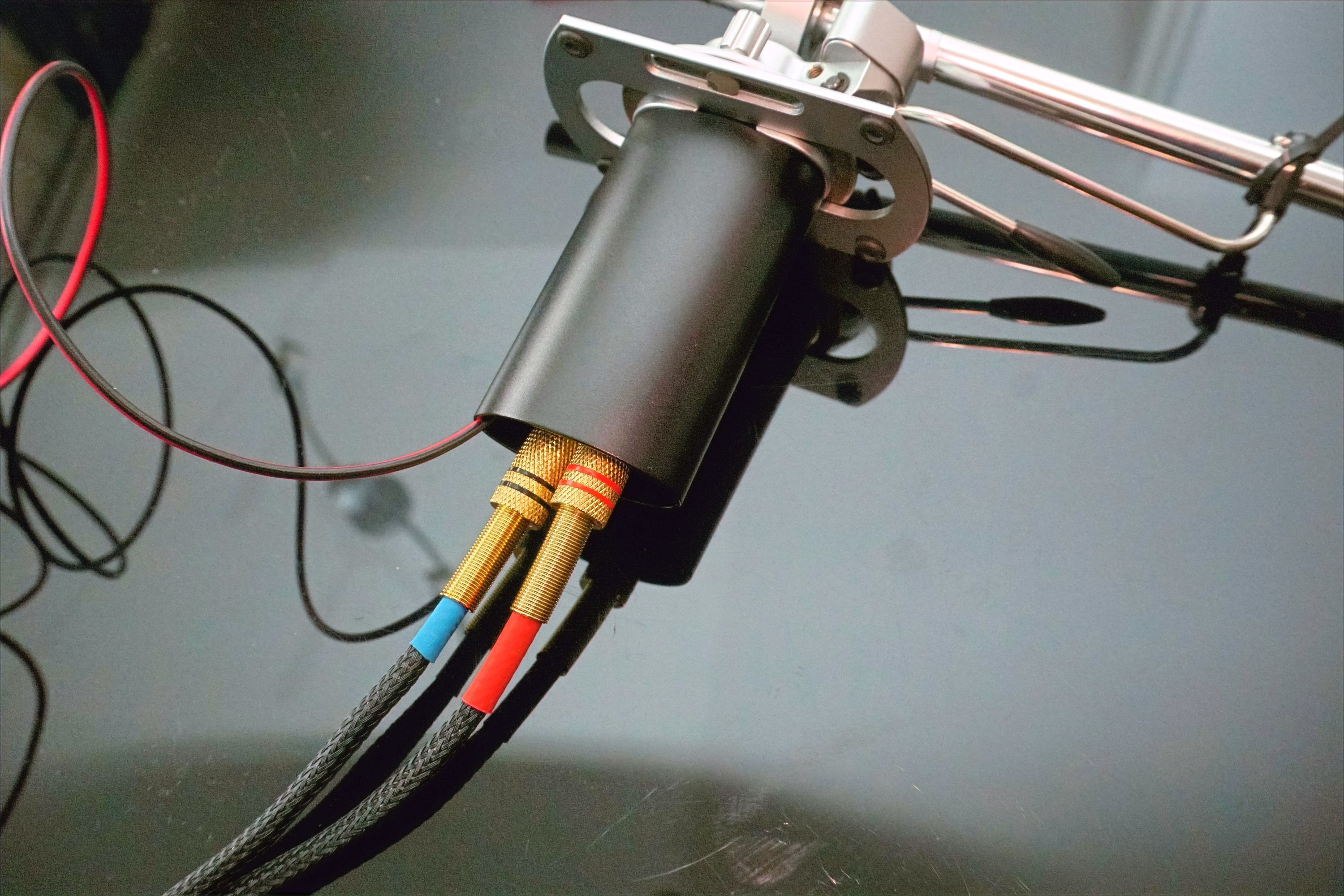

(9) Stick your favourite record on (with the platter spinning this time), cue up the record, pour yourself a glass of wine/beer/G&T, sit back and enjoy.įor lateral balance, I take off the main counterweight. (8) Adjust the arm height so that the arm tube is parallel to the surface of the record and tighten the adjustment screw. (7) Put a record of normal thickness onto the platter and set the stylus down onto it without the platter spinning use the 2g groove if you're tracking at 2g) but personally I usually go for about half the tracking weight value. Generally the advice is to set this the same as the tracking weight (i.e. (6) Re-hook the bias weight onto the rod on the bearing housing and put it in whichever groove you see fit. (5) Use the rider weight to dial up the tracking force that you want - the manual should show which graduation is for which tracking weight. (4) Return the arm to the rest and secure it (3) Un-clip the arm from the rest and use the main rear weight to zero balance the arm so that it floats horizontally. (2) Unhook the bias weight from the rod on the bearing housing. (1) Set the rider weight on the wayrod to its rearmost position.

0 kommentar(er)

0 kommentar(er)